Simple Ways to Improve Dimensional Planning in Projects

If you’ve ever been part of a construction project—or even just managed a home remodel—you already know how messy things can get when dimensions aren’t nailed down correctly. One tiny slip in planning, and suddenly the entire project feels like it’s sliding sideways. That’s the frustrating part. The good news? Getting dimensional planning right doesn’t have to be rocket science. With a bit of structure, teamwork, and the right tools, projects in the U.S. can run much smoother and avoid the kind of setbacks that drain budgets and patience.

Why Dimensional Planning Is a Big Deal

Think about putting together flat-pack furniture. Miss one measurement by even half an inch, and the whole piece looks crooked. Now stretch that problem across a bridge, a commercial high-rise, or a new production facility. That’s the scale of risk project managers deal with every day.

In the United States, mistakes aren’t just annoying—they’re expensive. Labor costs run high, regulations are tight, and timelines rarely allow room for rework. A single miscalculation might snowball into lost time, wasted money, and an unhappy client.

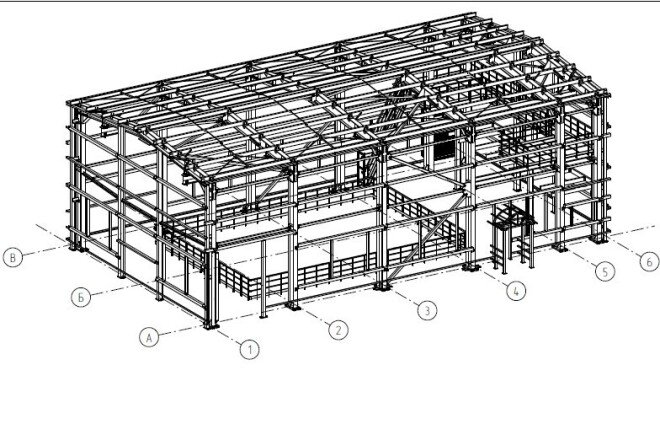

That’s why detailed references, like ga drawings, matter so much. They’re essentially the “map” that keeps everyone pointed in the same direction. When used properly, they reduce confusion, eliminate repeated fixes, and give teams the clarity they need to move forward without second-guessing.

Starting Strong with Documentation

Any successful project begins on paper—or more often these days, on a screen. But here’s the kicker: plans and documents only help if they’re clear enough for every player involved. On big U.S. jobs, there are usually several contractors, suppliers, and clients juggling overlapping tasks. If the paperwork doesn’t match up, problems spread quickly.

A smart move is to keep all documentation standardized. Same units, same notations, same formatting. It might sound basic, but mismatched details are one of the biggest culprits behind schedule overruns.

Even better? Go digital. Cloud-based tools now allow entire teams across states to update, view, and comment on documents in real time. That shift has been huge for American projects, where collaboration happens across multiple offices and time zones. It’s not just about convenience—it’s about avoiding the “I thought you meant inches, not millimeters” type of disaster.

Precision Is the Name of the Game

Sure, it’s obvious: accuracy matters. But pulling it off consistently is another story. Numbers themselves don’t lie—it’s the process behind collecting and verifying those numbers that tends to break down.

Take high-stakes industries like aerospace or large-scale infrastructure. Being off by even a fraction can delay a launch or stall a bridge project for months. That’s why more U.S. firms are leaning into advanced measuring tools like 3D scanners, laser equipment, and digital imaging. These minimize human error and deliver more reliable data.

Here’s another underrated trick: redundancy. Don’t just measure once. Re-check. Then have someone else confirm it. Yes, it might feel like overkill when the clock is ticking, but it saves way more time than redoing half a project later on.

It’s All About Talking to Each Other

One of the biggest misconceptions is that dimensional planning is a technical chore reserved for engineers or architects. Truth is, it’s a team effort. Designers, builders, managers, and even clients all need to see eye to eye. Communication breakdowns happen fast. Picture this: the design team specs a beam at 12 feet, but the crew cutting the material thinks it’s 11.5. That tiny slip can waste hours on-site.

That’s why U.S. companies are investing heavily in collaborative platforms where updates are shared instantly. Whether through project dashboards, scheduled video calls, or shared files in the cloud, keeping everyone in sync avoids last-minute “surprises.” Regular check-ins may sound tedious, but they keep costly delays out of the equation.

The Tech Tools Changing Everything

Dimensional planning isn’t stuck in the past. In fact, the digital revolution has flipped the entire process upside down. BIM (Building Information Modeling) has become almost standard for many U.S. projects. It’s not just a fancy 3D model—it’s a system that combines design, costs, materials, and timelines into a single workflow. That kind of integration doesn’t just look pretty; it reduces errors and improves accountability.

Then there are drones. Surveying used to eat up days or even weeks. With drones, teams can gather aerial data in a fraction of the time, often with higher accuracy. That information feeds directly into dimensional planning systems, allowing quicker decisions. Augmented reality is also making its mark. Imagine walking onto a job site and instantly seeing digital overlays of the finished design, matched against what’s physically in front of you. That makes spotting dimensional mismatches much easier—and fixes can happen before the mistake becomes permanent.

The Value of External Expertise

Sometimes, even the most capable internal team needs an outside perspective. That’s where consulting firms step in. In the U.S., organizations like strand consulting corporation provide specialized insight that many teams simply don’t have the bandwidth to develop on their own.

Bringing them in doesn’t signal weakness—it signals commitment to precision. These experts often spot risks earlier, introduce best practices, and streamline communication between multiple stakeholders. It’s like having an extra set of sharp eyes focused purely on keeping your project on track.

Training Makes or Breaks the Process

Here’s something people often overlook: dimensional planning is only as strong as the people handling it. You could throw the most advanced tools at your team, but if they’re not trained well, errors will creep in.

That’s why U.S. companies are ramping up training programs, certification courses, and workshops to ensure staff stay sharp. A workforce that understands both the technical side and the compliance requirements makes projects safer and more predictable.

Pairing junior team members with experienced mentors is another underrated approach. Real-world lessons, passed down on the job, can’t always be learned from a manual. That blend of formal training and hands-on guidance keeps standards consistent from one project to the next.

Compliance Can’t Be Ignored

Every project in the U.S. has to do more than meet deadlines. It has to meet regulations. Safety standards and building codes tie directly into dimensional planning. Get the numbers wrong, and you’re not just facing delays—you’re staring down possible legal issues or fines.

That’s why many project managers integrate compliance checks right into the planning process instead of tacking them on at the end. Software solutions now exist to track code updates, regional requirements, and documentation in real time. With regulations constantly shifting across states, automation here is a lifesaver.

Final Thoughts

At its core, dimensional planning might sound like a dry subject. But it’s really about one thing: avoiding chaos. In the fast-paced, regulation-heavy environment of the United States, sloppy planning can derail months of work in an instant.

The simple steps—clearer documentation, redundant checks, better communication, and smart tech adoption—are what keep projects steady. Add in ongoing training and, when needed, expert consultants, and you create a system that catches mistakes before they snowball.

Improving dimensional planning isn’t about overcomplicating things. It’s about consistent habits that protect budgets, timelines, and reputations. Projects run smoother, people feel less stressed, and clients walk away satisfied. And really, that’s what every team is aiming for at the end of the day.

Comments

You must be logged in to comment.

Latest Articals

-

Cosmetic Packaging Boxes – Enhance Your Brand’s Beauty Appeal

Cosmetic packaging boxes are the ultimate solution for brands that want to showcase their products with elegance and safety. They protect delicate items from damage while reflecting a professional brand image. A well-designed box instantly enhances the value of your cosmetics.These boxes also serve as a strong marketing tool. With creative designs and quality materials, they make products stand out on shelves. Cosmetic packaging boxes not only secure your items but also leave a lasting impression that attracts buyers and builds trust.The Importance of Cosmetic Packaging BoxesCosmetics are fragile and often sensitive to light, heat, and moisture. Packaging plays a vital role in maintaining their quality until they reach the customer. Boxes provide protection while ensuring your products remain fresh and damage-free.At the same time, packaging is more than just a shield. It communicates your brand identity through colors, styles, and materials. Cosmetic packaging boxes create a professional look that...

-

Pizza in Qatar? Say No More! 🍕

When hunger strikes, there’s only one thing on your mind—pizza. And not just any pizza… we’re talking about that hot, cheesy, melty slice of happiness from Pizza Hut Qatar. No more stressing over “pizza near me” or “pizza near by me.” Your cheesy soulmate is right here.Why Pizza Is Basically Therapy 🛋️💖Bad day? Grab a pizza. Good day? Celebrate with pizza. Bored? Order pizza.It’s the answer to literally everything. Forget self-help books—your cure is spelled P-I-Z-Z-A.Pizza Hut Qatar = The Real MVP 🙌You could scroll “pizza near me” forever, but let’s be real—nothing beats Pizza Hut. Whether you’re into a thin crust crunch or stuffed crust heaven, they’ve got the pizza game on lock.The Menu That Hits Different 🎯Cheese pulls, bold toppings, and flavors that slap—here’s what you’ll find at Pizza Hut Qatar:Margherita = simple but legendary 🌿🧀Pepperoni = the OG that never fails 🍖BBQ Chicken = smoky, tangy, perfection...

-

.jpg)

What Safety Hazards Can Be Prevented with Fireplace Repair in Orlando FL?

A fireplace is often seen as the heart of a home, providing comfort, warmth, and ambiance. Yet without proper care, it can quickly become a source of serious safety concerns. From gas leaks to chimney obstructions, every part of a fireplace system requires consistent maintenance and professional attention to avoid hazards. One of the most effective ways to protect your home and family is by scheduling timely Fireplace Repair Orlando FL.Why Does Fireplace Repair Matter for Safety?A fireplace may look safe while burning wood or using an electric or gas insert, but small unseen issues can escalate into large hazards. Cracked hearths, blocked chimneys, or malfunctioning ventless systems can lead to fires, carbon monoxide leaks, and other emergencies. When ignored, even minor repairs can compromise the entire fireplace structure and spread risks throughout the place. Professional companies in the local area have the specialists, technicians, and repairman teams who can...

-

Why Yuwei Bearing is Your Trusted Precision Bearing Manufacturer

In today’s competitive industrial world, the importance of high-quality components cannot be overstated. When it comes to machinery, vehicles, or automation equipment, the difference between average performance and exceptional reliability often comes down to the quality of the bearings used. This is where a trusted precision bearing manufacturer becomes a crucial partner for your business. Yuwei Bearing has established itself as a leading choice for companies seeking performance, durability, and innovation.As a renowned precision bearing manufacturer, Yuwei Bearing focuses on producing bearings that meet the highest standards of engineering excellence. Every bearing is designed with meticulous attention to detail, ensuring that it performs flawlessly under even the most demanding conditions. From standard ball bearings to specialized custom solutions, Yuwei Bearing offers a wide range of products suitable for multiple industries, including automotive, aerospace, robotics, and industrial machinery.What sets Yuwei Bearing apart is its unwavering commitment to quality. Each bearing undergoes...

-

.jpg)

What Safety Risks Can Gas Fireplace Repair Prevent in San Antonio TX?

A gas fireplace adds comfort, warmth, and convenience to any home, but like any mechanical system, it requires regular maintenance and occasional repairs to operate safely. When overlooked, small issues can quickly turn into serious hazards that threaten both property and health. Professional services help address these risks, ensuring safe operation and long-term efficiency. That is why it is crucial to understand what safety risks can be prevented with timely Gas Fireplace Repair San Antonio TX.Why Does Gas Fireplace Safety Matter in San Antonio TX?Fireplaces are designed to provide heat and ambiance, but if neglected, they can introduce harmful elements into the home. Gas leaks, carbon monoxide exposure, and ventilation problems are among the most serious concerns. Improper installation, aging components, or poor cleaning practices may allow dangerous gases to accumulate indoors. Regular service ensures the fireplace, inserts, and installation parts operate as intended. In a city like San Antonio,...

-

Unlock Your Engineering Potential with the Ultimate Robotic Arm Kit

Are you ready to take your engineering projects, hobby robotics, or learning experience to the next level? The Robotic Arm Kit from AiRobotBuy is your perfect companion for innovation, experimentation, and hands-on fun. Designed for both beginners and advanced users, this kit delivers precision, versatility, and durability, making it the ideal choice for anyone passionate about robotics.With the Robotic Arm Kit, you can build a fully functional robotic arm capable of handling small to medium tasks. Its impressive load capacity of up to 500 grams allows you to experiment with lifting, moving, and positioning objects with accuracy and reliability. Every component is engineered for smooth operation, ensuring that your projects perform seamlessly from start to finish.One of the standout features of this Robotic Arm Kit is its modular design. Every part is easy to assemble, adjust, and customize, giving you the flexibility to design your arm to match your unique...